If you don’t see an answer to your question please use our contact form to submit your questions.

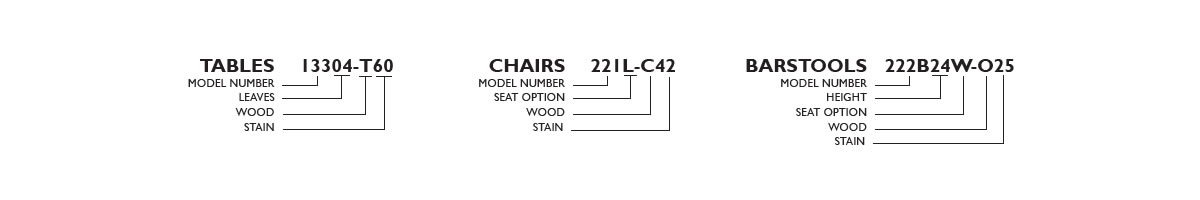

WHAT DO THE DESCRIPTIVE SYMBOLS REPRESENT?

WOOD

CHARACTER CHERRY

CHERRY

HICKORY

RED LEAF MAPLE

RED OAK

TWO-TONE

{STANDARD HEIGHT IS 30″}

30″ TALL

36″ TALL

42″ TALL

0 LEAVES

2 LEAVES

FABRIC

LEATHER

WOOD

24″ TALL

30″ TALL

TWIN

FULL

QUEEN

KING

CALIFORNIA KING

HOW TO CUSTOMIZE AN ORDER NUMBER.

DOES OAKWOOD OFFER A WARRANTY ON THEIR FURNITURE?

Yes, we do. You can view the details of our 10 year warranty here.

WHERE CAN I PURCHASE OAKWOOD FURNITURE?

Visit our Distributor Locator page to find the closest Oakwood distributor.

WHAT MAKES OAKWOOD FURNITURE DIFFERENT?

The quality is in the details. Some of the following details of our furniture are just a few things that make Oakwood furniture different:

WHAT IS THE OAKWOOD SUPER FINISH?

A tough catalyzed varnish is the only finish used by Oakwood. Therefore you get a durable, resistant finish on your table as well as each piece of Oakwood furniture. The finish is carefully applied and hand sanded between coats to achieve a smooth finish designed to last many years to come.

THE OAKWOOD SUPER FINISH IS RESISTANT TO THE FOLLOWING ITEMS:

⇒ VINEGAR

⇒ LEMON JUICE

⇒ MUSTARD

⇒ PERMANENT MARKER

⇒ INK

⇒ NAIL POLISH REMOVER

HOW DO I CARE FOR MY OAKWOOD FURNITURE?

⇒ If you choose to polish or wax your furniture use only

high quality products, preferably without silicone. Do

not pour directly onto furniture, apply to cloth first.

⇒ Sharp objects and some place settings that are rough

on the bottom edge can scratch a table top. Use

placemats or a tablecloth to prevent major scratching,

slight scratches will not harm the durability of the table.

⇒ Avoid placing furniture directly in front of heat sources.

⇒ Leaves unused for long periods of time may not exactly

match a table top that has been exposed to sunlight,

daily use and cleaning.

⇒ Consider using a humidifier and an air conditioner to

keep your home’s relative humidity between 30-50%.

⇒ Solid wood will always seek a balance with its

surroundings. In the home, it loses moisture to

extremely dry air and contracts. As a result, table top

halves may part slightly. Conversely, when humidity is

high, wood absorbs moisture from the air and expands

slightly. In either case it regains its original

dimensions as humidity stabilizes. However, even

after years of adapting to humidity cycles, solid

wood will retain all the sturdiness and good

looks it had the day it was made.

Britta burrus design.

Britta burrus design.